The transmission shaft is a rotating body with high speed and few supports, so its dynamic balance is crucial. Generally, the transmission shaft shall be subject to dynamic balance test before delivery and adjusted on the balancing machine. For front engine rear wheel drive vehicles, it is the shaft that transmits the rotation of the transmission to the final drive. It can be several joints, and the joints can be connected by universal joints.

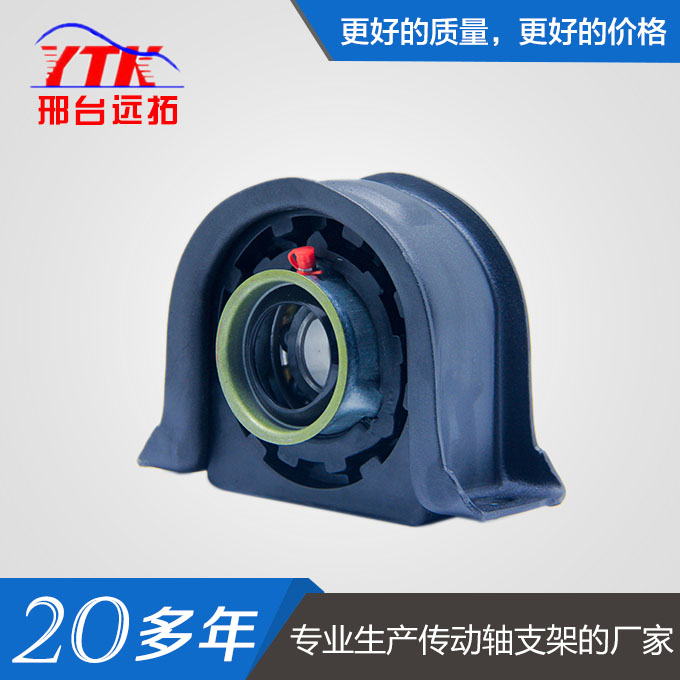

The transmission shaft is composed of shaft tube, expansion sleeve and universal joint. The telescopic sleeve can automatically adjust the change of the distance between the transmission and the drive axle. The universal joint is used to ensure the change of the angle between the two axes of the transmission output shaft and the drive axle input shaft, so as to realize the constant angular speed transmission of the two shafts.

The cause analysis of the loose transmission shaft bracket is as follows:

1. The flange connections (or connecting bolts) of the drive shaft are loose, causing a noise.

2. The lubricating grease fittings (commonly known as grease fittings) and cross shaft oil passages are blocked and cannot be filled with lubricating grease, and the lubricating grease and cross shaft oil seal are not filled on schedule.

3. The installation configuration to the cross shaft is too tight.

4. Loose fitting between the sleeve and the universal joint fork hole and loose bolt of the support plate affect the sleeve operation, causing excessive wear of the universal joint fork hole and loose noise.

5. The spline of the second shaft of the gearbox and the spline in the flange are worn too much, resulting in looseness and noise.

Mobile station

WeChat